The world hydrogen energy market is in the early stage of explosive growth, and the increasing demand for hydrogen fuel has also led to the expansion of hydrogen energy facilities around the world. With the rapid development of the hydrogen industry, an increasing number of hydrogen refueling stations (HRS), whether stationary or mobile, are being built in urban areas with a high density of buildings and population. As a kind of emerging clean fuel, hydrogen is also highly flammable and explosive. So, the risk of multiple accidents in urban HRSs has attracted more and more concern. Mobile hydrogen refueling stations are advantageous because they can be moved between locations to provide refueling. However, there are serious concerns over the risk of various accident scenarios as the refueling stations are transported. In this paper, Dong-Hwan Kim and his team conducted a quantitative risk assessment of a mobile hydrogen refueling station. And also analyzed the risks that may occur at two refueling locations and the transport path between them. During the demonstration process, Kong-Hwan Kim and his team's demonstration process revealed that risks are mostly in an acceptable zone and to a lesser degree in a conditionally acceptable zone. The demonstration concluded that the single greatest single risk for hydrogen refueling station factor is an accident resulting from the rupture of the tube trailer at the refueling site.

In 2019, South Korea published the “Roadmap for Hydrogen Economy Revitalization” in order to achieve a “green hydrogen society” where hydrogen energy is utilized comprehensively. In 2021, referring to the “Korean version of the New Deal” as a large-scale national project, the South Korean government decided to promote the expansion of green mobility such as hydrogen cars with the aim of “net-zero” society in response to the global climate change agreement. Last year, the world’s first “Act on the Promotion of Hydrogen Economy and Safety Management” was established. The institutional foundation to implement a hydrogen economy was laid by providing policies for six major areas, including R&D, infrastructure, hydrogen vehicles, refueling stations, safety, and standards, and by founding a hydrogen economy committee. Through these efforts, 170 hydrogen refueling stations have been built in South Korea as of June 2022, including 100 stations built over the past 2 years. Also, hydrogen energy infrastructure has been rapidly expanding as models are developed for stand-alone hydrogen refueling stations and for hydrogen multi-energy stations, packaged hydrogen refueling stations, and mobile hydrogen refueling stations.

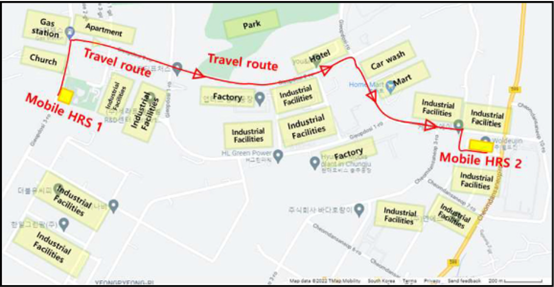

Figure 1 – Concept of a mobile hydrogen refueling station

In South Korea, mobile hydrogen stations can be built according to the Ministry of Industry's Exemption Standards (Ministry of Industry Notice No. 2018-179, October 1, 2018 “Exemption Standards for Multi-energy, Packaged, and Mobile Car Charging Facilities”). As shown in figure 1, a mobile hydrogen station is a vehicle equipped with transportable facilities required to refuel automobiles that use hydrogen as fuel and is specified to have a processing capacity of 30m3 or greater (excluding facilities refueling with stored pressure rather than with pressurization devices such as a compressor). Since a mobile hydrogen refueling station can be transported between authorized locations, it has the advantage of being able to respond to the demand for refueling hydrogen electric vehicles at numerous sites on the outskirts of a city in the initial stages of hydrogen infrastructure development. If the demand increases, stationary hydrogen refueling stations can be built on existing sites while mobile hydrogen refueling stations are moved to other suburbs to provide hydrogen infrastructure.

However, because a mobile hydrogen refueling station is transported between refueling sites with the core facilities (including compressors, storage containers, and dispensers) mounted on the refueling station vehicle, a leak of the ultra-high-pressure (82 MPa) hydrogen gas in the confined space can result in fire and explosions, Therefore, it is necessary to analyze and mitigate risk factors to ensure safety.

In most previous studies on hydrogen refueling station risk assessment, the risk is presented while core equipment is fixed. However, In the case of mobile hydrogen refueling station, it is necessary to consider the risks associated with potential leakage that may occur as fittings loosen due to vibration during transportation from one place to another. Therefore Kong-Hwan Kim and his team also did the quantitative risk assessment (QRA) associated with the travel route. Accident scenarios involving leaks and ruptures in each facility component were derived to analyze the risk factors of a mobile hydrogen refueling station that is planned to be built for the demonstration sites in Chungj-si, Chungcheongbuk-do in April 2022. Based on the derived scenarios, a QRA was performed to determine the safety and implications of the mobile hydrogen refueling stations.

Mobile Hydrogen Refueling Site (HRS) location description:

Figure 2 shows the demonstration refueling station sites 1 and 2 along the travel route in the City of Chungju, South Korea. Industrial facilities, churches, gas stations, hotels, shopping marts, and bus stops are located along the route of the mobile hydrogen refueling station. The refueling station can be moved from mobile hydrogen refueling station site 1 to provide refueling at mobile hydrogen refueling station site 2. Site 1 is scheduled to be built in the first half of 2022 adjacent to a six-lane roadway. A tube trailer will be installed at the site to supply hydrogen to the mobile hydrogen refueling station, which can be moved to the other sites (2, 3, and 4) for refueling. This study assessed the risks of a mobile hydrogen refueling station by selecting a virtual site 2 approximately 3 km from site 1.

Figure 2 – Travel route and mobile hydrogen refueling sites (HRS) 1 and 2.

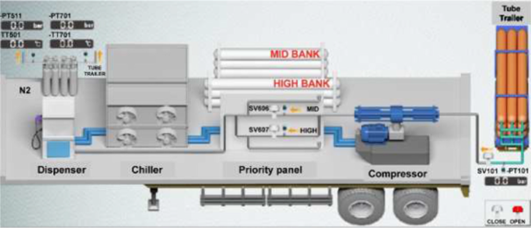

The subject of this study is the Chungju Mobile HRS, which is scheduled to be built as a mobile hydrogen refueling station for refueling hydrogen electric vehicle. This will be the first ever refueling station of this type in South Korea. As shown in Figure 3, the core facilities for the mobile HRS are mounted on a trailer manufactured in the wing-body form. The core facilities include a compressor, hydrogen storage system, dispense, hydrogen gas detector, flame detector, and a chiller to decrease the hydrogen temperature, as shown in Figure 4. Table 1 shows the specifications for each component.

Figure 3 – Chungju mobile hydrogen refueling site.

Figure 4 – Mobile hydrogen refueling site diagram.

To perform the QRA research, virtual accident scenarios were constructed during a qualitative hazard and operability (HAZOP) study (Table 2). Five representative scenarios were selected among various risk scenarios obtained through the HAZOP, which are all based on leaks caused by poor connections between the tube trailer, pipe joints, and other facilities. DNV GL’s SAFETI 8.4 program, an accident damage calculation program which is widely used in risk assessment studies, was used to confirm the level of damage by the radiant heat and explosion overpressure from a gas leak and severe rupture of each core facility of the hydrogen refueling station.

Accident occurrence data for accident scenarios:

Table 3 lists the small-scale (cross-sectional area of 1% A) and large-scale leaks (cross-sectional area of 10% A) based on leak hole size in the core facilities of the HRS. The Hydrogen Risk Assessment Models 3.0 (HyRAM 3.0) program developed by the SANDIA National Laboratory at the U.S. Department of Energy was used to generate the leak frequency and ignition probability based on the facilities and components of the actual mobile hydrogen refueling station to be built.

Mobile Hydrogen Refueling Station QRA Results:

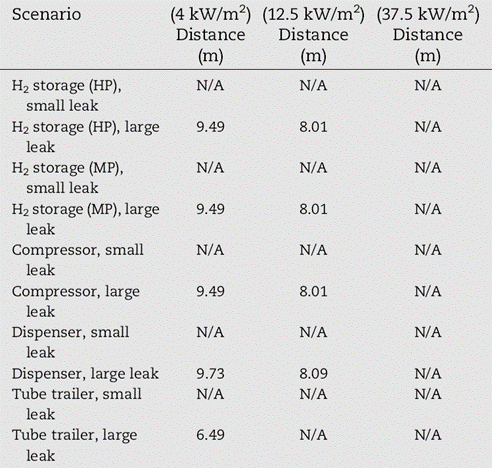

Table 4 – Distance of impacts from thermal radiation.

In the event of a leak accident with hydrogen, which is a combustible gas, flame jets may occur from immediate ignition by the ignition source, resulting in radiant heat and human/material damage. Table 4 summarizes the results of the jet fire effect evaluation under the selected accident scenarios. Exposure to radiant heat of 4 kW/m2 or higher can lead to casualties such as burn victims. Exposure to radiant heat of 12.5 kW/m2 or higher can ignite wood or melt plastic, and a radiant heat of 37.5 kW/m2 or higher is sufficient to damage process machinery.

The results of the jet flame evaluation based on the accident scenarios indicated no damage impact for the tube trailer, compressed gas facility, refueling facility, and processing facility in the event of a small leak. In the event of a large leak, casualties resulting from burns may occur within approximately 10m, and the radiant heat may result in property damage by igniting wooden structures or melting plastic within approximately 8m. The evaluation indicated no radiant heat intensity strong enough to damage process machinery.

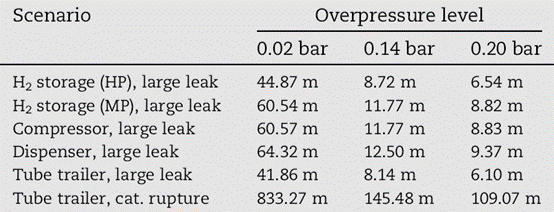

Distance of damage impacts from explosion overpressure:

If a large amount of hydrogen gas leaks and combusts rapidly, an explosion may occur due to the instantaneous discharge of heat and pressure, resulting in damages by explosion overpressure. The results of explosion pressure impacts are summarized in Table 9. Exposure to an overpressure of 0.02 bars or higher can damage 10% of the roof and windows of houses. An exposure of 0.14 bars or higher can slightly damage walls and roofs of nearby houses, and an overpressure of 0.2 bars or higher is intense enough to damage steel structures of buildings.

Table 5 – Distances affected by overpressure.

The results of the explosion overpressure evaluation based on the accident scenarios indicated no damage impacts by overpressure in the event of a small leak because no jet fire was measured. In the event of a large leak, an overpressure strong enough to damage steel structures of buildings within 10 m was observed. In addition, the distance of damage impacts by the overpressure caused by the rupture of the tube trailer was 109.07 m, which could lead to a major accident.

Individual and societal risk assessment results:

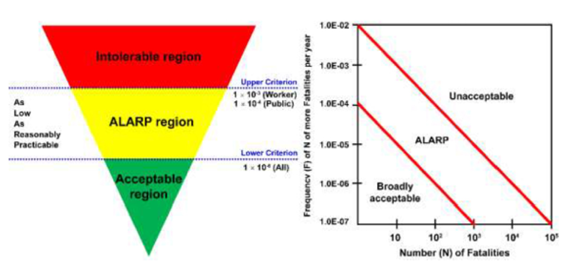

A risk assessment for mobile hydrogen refueling stations is the process of identifying risk factors for the core facilities and determining the likelihood (frequency) and intensity of occurrence so preventative measures may be established and implemented. Risk is defined as the product of the consequence and frequency of an accident. The criteria widely accepted and proposed by HSE in the UK were adopted to analyze the risk of the mobile HRS. These were categorized into “intolerable/unacceptable,” “as low as reasonably practicable (ALARP),” and “acceptable zones,” as shown in Figure 5.

Figure 5 – Risk criterion (Health and Safety Executive, U.K.) for workers and the public.

The installation of at-risk facilities is prohibited in the intolerable zone. In the ALARP zone, facilities are permitted but risk management and improvement measures must be undertaken to lower the risk. The installation of facilities is permitted without additional measures in the acceptable zone.

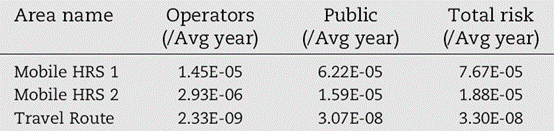

Individual risk is the risk of exposure for people present near the source of risk and is expressed as an interval of time by calculating the probability for an individual to experience severe injury or death in a dangerous environment. The total risk of the mobile hydrogen station was 7.67×10-5 at Site 1, 1.88×10-5 at Site 2, and 3.30×10-8 during transport. These risk factors satisfied the risk criteria (ALARP Zone) suggested by the HSE for the workforce and public (Table 6).

Table 6 – Individual risk results of the mobile HRS

Figure 6 – Iso-contour (individual risk) of the mobile hydrogen refueling site (HRS).

Figure 6 illustrates the range of individual risk in the iso-contour of the mobile hydrogen refueling station as the subject of this study. As a result of the individual risk simulation, there was no risk area falling in the Unacceptable/Intolerable Zone as proposed by the HSE. The individual risk in the mobile HRSs fell in the ALARP zone, and the individual risk along the travel route fell in the Acceptable Zone.

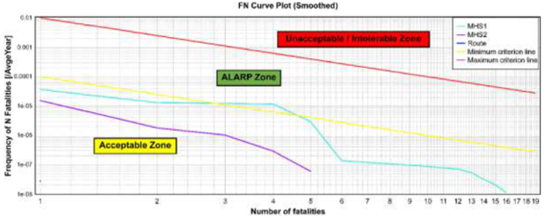

Societal risk is the probability that a certain number of people within a group simultaneously exposed to the impacts of an accident will be adversely affected by the accident. It is expressed in an F-N (frequency-number of fatalities) curve as a relationship between the expected frequency of N fatalities and the resulting actual number of fatalities. As shown in Figure 7, the F/N curves indicated that the societal risk of mobile HRS 1 mostly fell in the acceptable and ALARP zones, and that of mobile HRS 2 and the travel route fell in the acceptable zone. Based on the societal risk results, we suggest that the mobile hydrogen station as the subject of this study can be constructed with acceptable risk levels.

Figure 7 – Societal risk of mobile hydrogen refueling station.

The team concluded that the individual and societal risks in most sections fell in the acceptable zone and to a lesser degree in the conditionally acceptable (ALARP) zone from the QRA conducted on this mobile hydrogen refueling station. It is expected that the subject mobile hydrogen refueling station can be safely built within acceptable risk levels.

From the experimental results, the study team believes that to reduce the possibility of mobile HRS leakage, it is necessary to prevent leaks through regular maintenance of safety devices such as gas leak detection warning devices, emergency shut-off devices, and safety valves. Additionally, conducting a periodic inspection for any faulty connections, damage, and failure of the core facilities caused by vibration each time the refueling station is transported will ensure the safe operation of the station.

Kim, D.-H., Lim, J.-Y., Park, W.-I., & Joe, C.-H. (2022). Quantitative risk assessment of a mobile hydrogen refueling station in Korea. International Journal of Hydrogen Energy, 47(78), 33541–33549.

https://doi.org/10.1016/j.ijhydene.2022.07.194

Sun, K., Pan, X., Li, Z., & Ma, J. (2014). Risk analysis on mobile hydrogen refueling stations in Shanghai. International Journal of Hydrogen Energy, 39(35), 20411–20419.

https://doi.org/10.1016/j.ijhydene.2014.07.098